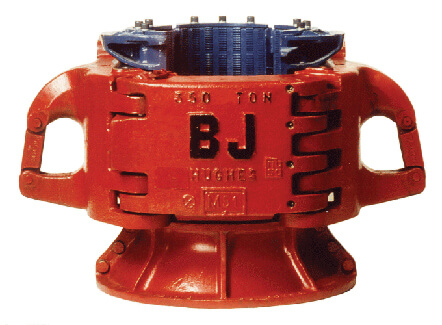

The elevator/spider tool is designed for lifting and suspending tubular goods, from light tubing to heavy wall pipe and drill collars.

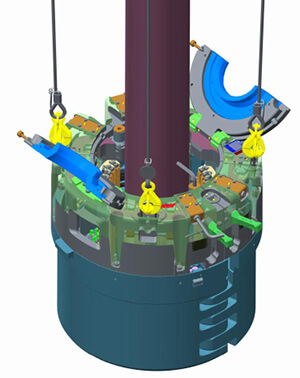

The main body of these units can be dressed as a casing elevator or as a spider. The upper unit is dressed as an elevator, using a bottom guide and a bell guide. The lower unit is dressed as a spider, using a top guide to aid in centering the casing.

The elevator is attached to the derrick traveling block and hook with 250, 350, 500, 750 AND 1,000 sTon standard Varco weldless links. The spider can be placed directly on the master bushing or rotary, assuming flat and sufficient contact surface is assured. If the load rating of the rotary table is less than the capacity of the elevator/spider, or if the rotary table surface is not flat, a NOV adapter plate may be used.

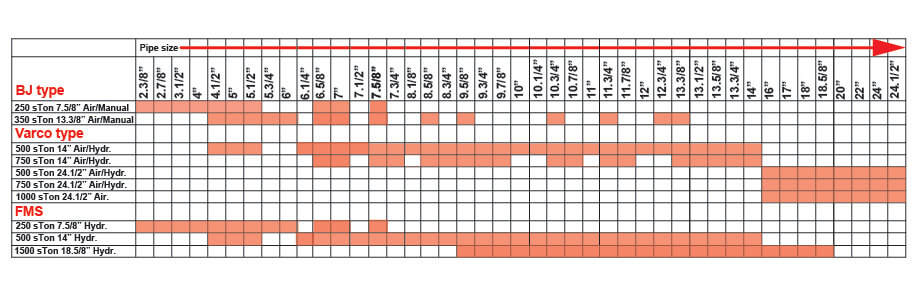

The elevator/spider tools are available air operated as well as hydraulic operated. See below overview. FMS Flush AND Floor Mounted Slips

The FMS275/375/495 is a hydraulic operated power slip which is equipped with replaceable slips and insert carriers to handle casing. The power down force generated allows the FMS to take the torque reaction of the tong when the string weight is not sufficient to resist rotating and eliminates the need for a manual casing tong. The powered down slips allow the first casing joints to be run in with the FMS.

The FMS is mounted flush with the rig floor, allowing the casing connection height to be lowered 1 meter (3 feet), thus eliminating the need for scaffolding. The rig crew also has more room to work by removing the spider body from the top of the rig floor.

The FMS can be used in combination with the rotary support table. The slips will set or raise when a command is given by the driller. Setting and raising slips of the FMS is remote controlled. By detecting the signal-line pressure from the FMS it is determined that the FMS slips are set.

The FMS275 utilizes the full range of slip assemblies and bottom guides, 2.3/8" to 7.5/8", as used in the existing BJ type 250 sTon elevator/spider.

The FMS375 utilizes the full range of slip assemblies and guides, 4.1/2" to 14", as used in the 500 sTon elevator/spider. The FMS375 is provided with standard rotary locks in case the rotary torque needs to be transmitted to the casing string.

The FMS495 utilizes the full range of slip assemblies and guides, 9.5/8” up to 18.5/8”. The FMS495 is provided with standard rotary locks in case the rotary torque needs to be transmitted to the casing string.

The FMS495 Hydraulic Flush Mounted Slip is a series of rotary equipment which has been developed to handle casing and covers a range from 9.5/8” – 18.5/8” using replaceable slips and insert carriers. The FMS495 has been designed to meet the need for bigger and higher capacity casing tools that increase running efficiency and safety due to the increasing amount of deepwater rigs drilling in deep water. The Flush Mounted Spider is capable of handling casing string weights up to 1,500 sTon / 1,361 Tonne depending on casing size.