As the versatile, safe, and dependable solution for making tubular connections on the drill floor, our iron roughnecks minimize rig floor hazards and streamline the make-and-break process. NOV's Iron Roughnecks are available from World Petroleum Supply serving the globe.

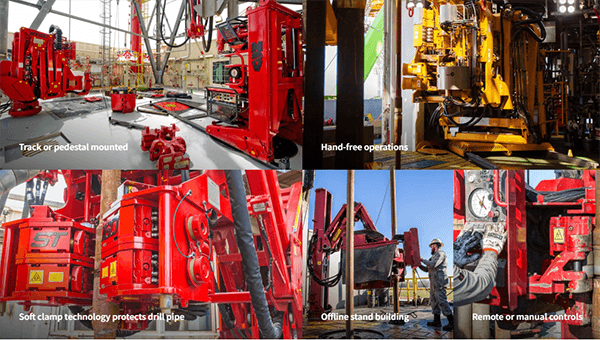

Since Varco introduced the “Big Foot” roughneck in the 1970s, NOV has proven to be the pioneer among iron roughneck manufacturers in developing the most versatile and dependable solutions for handling tubular connections on the drill floor. We have an iron roughneck design for every onshore and offshore drilling application. This includes varying levels of automation, multiple control options, and pedestal or track mounted interfaces. Our iron roughnecks minimize rig floor hazards and streamline the make-up and break-out process, maximizing your uptime and improving crew safety.

Global Operation Drilling Contractors find the Bulldog Iron Roughneck series perfect for land or offshore drilling rigs, harsh-environment operations, Extended Reach Drilling, and ERD. Need information contact World Petroleum Supply, Inc.

Drillform’s Bulldog AW120 Automated Floor Wrench facilitates integration into existing rig automation systems. Design features allow for remote diagnostic capabilities, preventative maintenance, and the ability to track and record data on each connection. With a focus on creating a safer operating environment for those on the rig floor, the AW120 features restricted access to the rotating zone and a hands-free operating system. World Petroleum Supply, Inc stocks the Drillform Bulldog AW120 AFW Iron Roughneck for global distribution.

Drilling Contractors find Drillform's Bulldog AW160Iron Roughneck's features and attributes for Harsh-Environment Operations, Extended Reach Drilling, ERD, deepwater Offshore and Global operations perfect. The additional safety features of more hands-free and the AW160 works on various sized projects. Need information contact World Petroleum Supply, Inc.

The Bulldog First Gen Automated Floor Wrench is still in operation today. This wrench, developed in 2014 proving the 360 deg technology is superior. Drillform’s new AW120 wrench incorporates all of the first generation features and more, in the same small package of this first Gen!

All of the Bulldog floor wrenches remove personnel from the rotating zone and takes automation of the rig floor to the next level. Designed for seamless integration into existing rig systems, its industry leading automation systems provide remote diagnostics capabilities, tracks and records data on each connection and facilitates predictive maintenance.

Drillform’s Bulldog AW160 Automated Floor Wrench facilitates integration into existing rig automation systems. Design features allow for remote diagnostic capabilities, preventative maintenance, and the ability to track and record data on each connection. With a focus on creating a safer operating environment for those on the rig floor, the AW160 features restricted access to the rotating zone and a hands-free operating system.