After years of limited changes in the development of BOP design, National Oilwell Varco's line of Shaffer'" NXT BOP Systems offers the drilling industry improved drilling economics in a new generation of well control systems. This new generation BOP has changed the performance expectations for pressure control equipment, offering significant operational advantages and features.

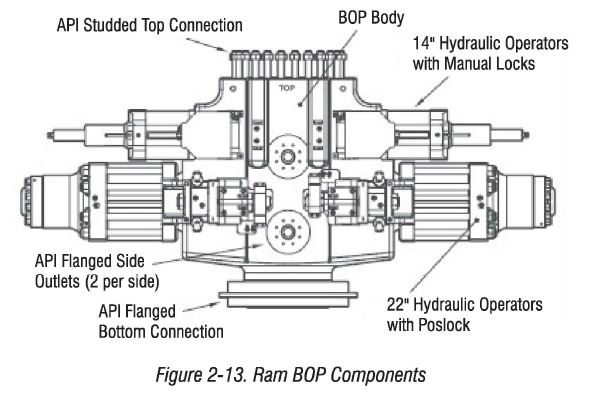

The NXT includes XT'" "Boltless Doors" and a "No-Weld Cavity". Single, double and triple cavity models are available for working pressures of 5,000, 10,000 and 15,000 psi. The double and triple models save space and weight by combining two or three ram compartments into one unitized body. Lock options include Poslock®, Ultralock'", and Manual Lock systems. NXT BOPs are manufactured in accordance with API Specification 16A, Third Edition, June 2004 and NACE MR0175 per API Specification 16A, Temperature T20

NOV's Shaffer NXT BOP offers a number of benefits and has significantly improved safety and efficiency, with quick access using boltless doors.

Features:

National Oilwell Varco Shaffer® BOP Systems are unique in highlighting a means of significantly improving safety and efficiency in the critical path of activity. With the replacement of the large door bolts in ram BOPs Shaffer has eliminated the manual practice of using brute force to torque up a series of large bolts. With the elimination of the large doors bolts in these ram BOPs, Shaffer'" has eliminated the time-consuming practice of using hydraulic tools to manually torque-up multiple door bolts. There are a number of benefits with this development.

The NXT "Boltless Door" assembly is mechanized using hydraulics to lock, unlock, open and close the door. The lock and unlock process is done with hydraulic cylinders mounted on the doors used to engage and disengage a locking bar system. These load bearing lock bars, housed in the door grooves, lock the door and body together.

Hydraulic power to operate a Model NXT ram BOP can be furnished by any standard oil field accumulator system. Hydraulic passages drilled through the body eliminate the need for external manifold pipes between the hinges. Each set of rams requires only one opening and one closing line. There are two opening and two closing hydraulic ports, clearly marked, on the back side of the BOP. The extra hydraulic ports facilitate the connection of the control system to the preventer.

A standard hydraulic accumulator unit will close any model NXT ram with rated working pressure in the well bore.

The Introduction of the NXT® Ram BOP was initially in the 18-¾”, 15,000 psi size. This system was designed to enable a stack height and weight package similar to a 13-5/8” BOP configuration and provide the capability of eliminating the dual stack drilling system with a through bore wellhead connector. Actuation of the boltless door mechanism is available in two configurations:

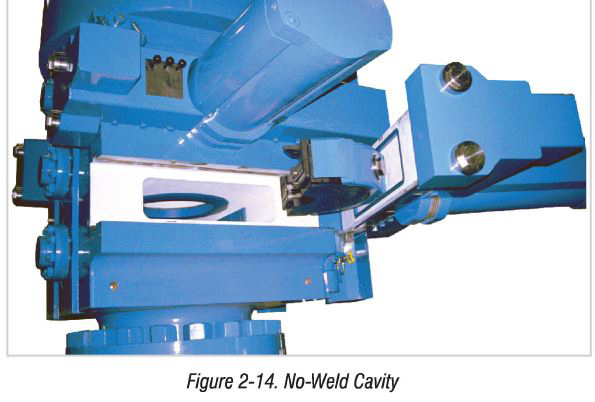

Shaffer's no-weld cavity feature, introduced in the SLX model ram blowout preventer, is standard on the NXT ram blowout preventer. This no-weld cavity feature allows upgrade of the BOP to "as new" condition by introducing replaceable parts to the cavity. Post-weld heat treatments and extensive in-shop repairs are thus eliminated. The no-weld cavity has a replaceable seal seat, a replaceable skid plate and replaceable side pads.

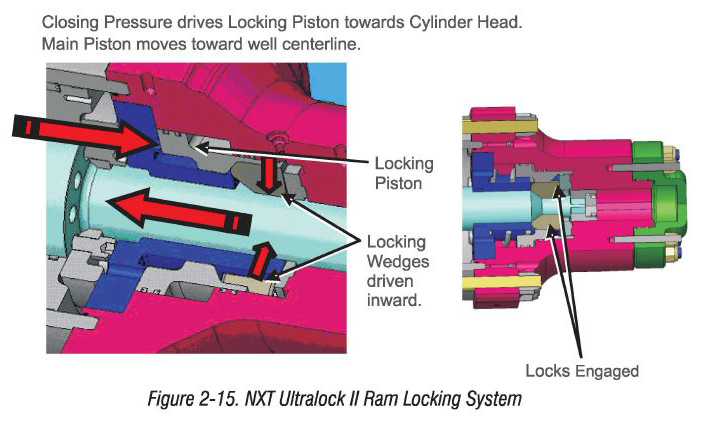

The Ultralock II locking system incorporates a mechanical locking mechanism within the piston assembly. This locking system is not dependant on closing pressure to maintain a positive lock. It uses flat tapered locking segments carried by the operating piston which engages another stationary tapered shaft located within the operating cylinder.

The system needs no adjustments, no matter the size of the pipe rams. Different size or type ram assemblies can be freely interchanged.

Only one hydraulic function is required to operate the cylinders open/close function and the locking system. The system automatically locks in the closed position each time the piston assembly is closed. Once the operating piston is closed on the pipe, the locks are engaged until opening pressure is applied. Only hydraulic pressure can unlock and reopen the preventer.

NXT preventers equipped with Poslock pistons are locked automatically in the closed position each time they are closed. The preventers will remain locked in the closed position even if closing pressure is removed. Open hydraulic pressure is required to reopen the pistons. The hydraulics required to operate the Poslock are provided through opening and closing operating ports. Operation of the Poslock requires no additional hydraulic functions, such as are required in some competitive ram locking systems.

Manual-lock pistons move inward and close the rams when closing, hydraulic pressure is applied. If desired, the rams can be manually locked in the closed position by turning each locking shaft to the right until it shoulders against the cylinder head. Should hydraulic pressure fail, the rams can be manually closed and locked. They cannot be manually reopened.

Manually locking shafts are visible from outside, and provide a convenient ram position indicator. Threads on the manual locking shaft are enclosed in the hydraulic fluid and are not exposed to corrosion from mud and salt water or to freezing.

Manually locking shafts are visible from outside, and provide a convenient ram position indicator. Threads on the manual locking shaft are enclosed in the hydraulic fluid and are not exposed to corrosion from mud and salt water or to freezing. See RAM BOP Lock Option Section.

Note that rams are priced separately from the BOP, and the customer is asked to specify the ram sizes to be installed in the cavities at the time of order placement.

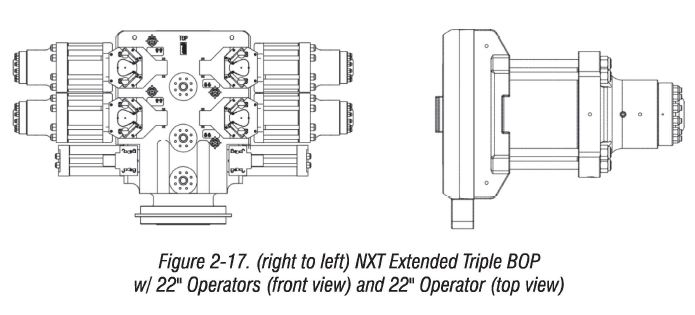

Three styles of shear booster operators are available. The standard NXT body is available with the Super Booster with a Poslock'" system aided by two tandem boost pistons. This produces the force required to shear today's high CHARPY drill pipe. The 14" x 14" (35.6 mm x 35.6 mm) compact shear booster design incorporates a Poslock system with a single 14" diameter boost piston. The 14" x 14" compact design is also capable of shearing today's high CHARPY drill pipe with 3,000 psi operating pressure. The preferred-offering extended NXT body incorporates a 22" shear operator with a 5,000 psi working pressure (see figures) and Poslock® system. This operator is designed to shear the latest offering of 5"Va" high CHARPY drill pipe, large diameter casing, and the future offerings of larger diameter (6"Va") high CHARPY drill pipe without a booster. While capable of operating with a 3,000 psi hydraulic supply, the 22" operator reaches full capability when a 5,000 psi hydraulic system is used as its supply. A 3,000 psi hydraulic system provides similar shear force to that of the Super and Compact booster operators.

Hydraulic door functions are operated through a control manifold assembly. The assembly is mounted to a plate for convenient customer installation.

The lower BOP ram cavity may be ordered "inverted" to seal on pressure above the ram assembly. This optional configuration of the ram cavity permits surface pressure testing of the BOP without the need to trip a test plug. Note: The test cavity is not bidirectional; that is, it does not seal with pressure below the rams.

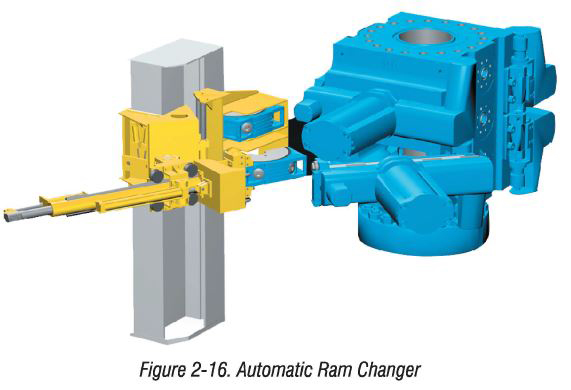

The Automated Ram Changing System (ARC®) has the potential to dramatically reduce, and possibly eliminate, lost time incidents by removing all hands-on activity involved in changing rams. Manpower may be reduced by 50% allowing for ram changing activities to be performed by a crew of 1-2 instead of the 4-5 conventionally required. Safety of rig personnel and cost savings realized are just some of the benefits of using the ARC®.

A ram-changing arm quickly and accurately retrieves and replaces rams in minutes, from a simple removable storage magazine.

Features of the ARC® include:

View Packing Elements and Seal Kits from World Petroleum Supply.