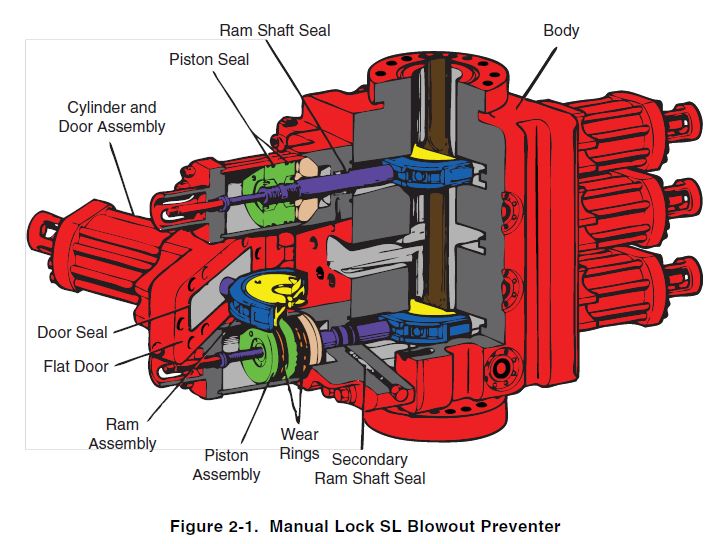

The Shaffer® Manual Lock Model SL Ram Blowout Preventer (SL BOP) provides a rugged, reliable preventer that is easily serviced in the field.

Special features include:

The Manual Lock SL BOP is available in single, double, and triple models. The manual provides the installation, operation, and maintenance procedures for all Manual Lock SL BOP models.

| Working Pressure | Size | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| psi | bar | in | mm | ||||||||||

| 15,000 | 1,035 |

|

|||||||||||

| 10,000 | 690 |

|

|||||||||||

| 5,000 | 345 |

|

|||||||||||

| 3,000 | 207 |

|

|||||||||||

These high-pressure, heavy-duty BOPs are designed for drilling and workover service. They are hydraulically operated and can be manually locked by rotating the handwheels. Units can be manufactured for Arctic (to −75°F). Shaffer preventers are manufactured in accordance with the American Petroleum Institute (API) specification API Spec. 6A (current edition) and the National Association of Corrosion Engineers (NACE) document “NACE Standard MR-01-75” (current revision).

Hydraulic operating fluid can be supplied by an NOV Koomey® or other BOP Closing System. 1,500 psi (103 bar) hydraulic pressure will close any model SL ram BOP with rated working pressure in the wellbore, except for the 11″ (279.4 mm) and 13-5/8″ (346.1 mm) 15,000 psi (1,034 bar) BOPs, which require 2,200 psi (152 bar). The 11″ (279.4 mm) and 13-5/8″ (346.1 mm) will close against 10,000 psi (690 bar) well pressure with less than 1,500 psi (103 bar) hydraulic pressure. However, to hold 15,000 psi (1,034 bar) wellbore pressure requires 2,200 psi (152 bar) hydraulic closing pressure. At the operator’s discretion, 3,000 psi (207 bar) closing hydraulic pressure may be used on all SL model preventers.