National Oilwell Varco's Shaffer Spherical BOP is one of the first lines of defense in controlling a well. When actuated, hydraulic pressure operates the piston, and in turn closes the spherical. The Spherical's closure occurs in a smooth, simultaneous upward and inward motion, as opposed to horizontal motion..

FEATURES:.

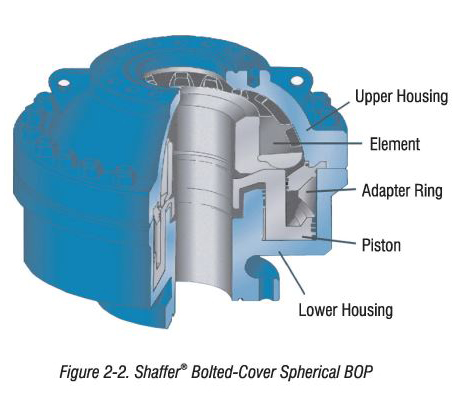

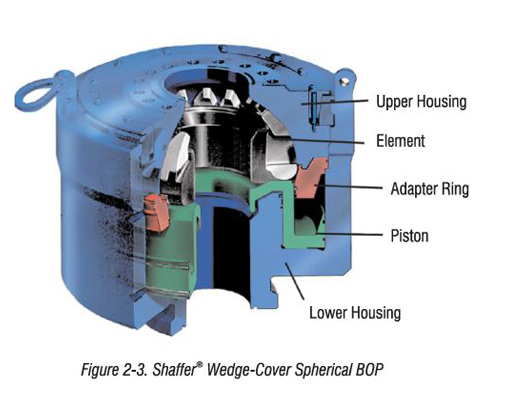

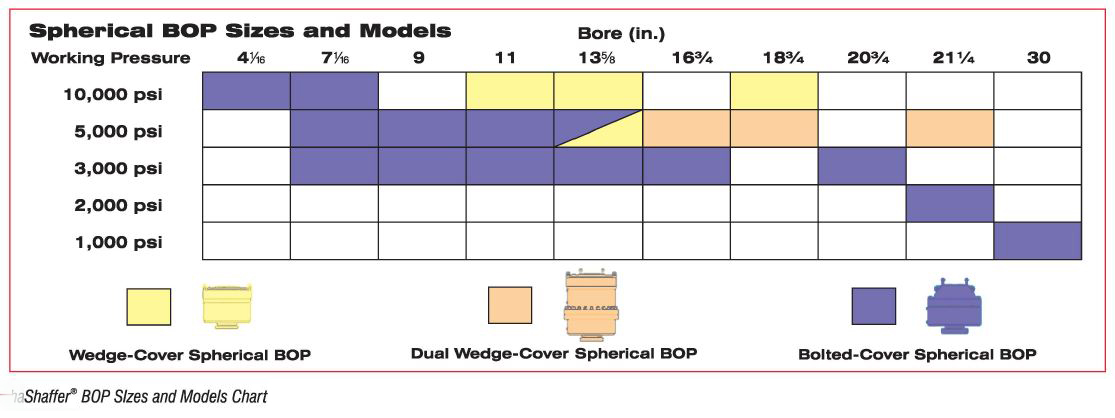

Shaffer® Spherical blowout preventers are compact, annular type BOPs that seal reliably on almost any shape or size kelly, drill pipe, tool joint, drill collar, casing or wireline. Sphericals also provide positive pressure control for stripping drill pipe into and out of the hole. They are available in bolted cover, wedge cover, dual wedge cover and NXT models that contain each of the following special features:

The success of NOV's Shaffer Sphericals is due primarily to the ruggedness and reliability of their sealing element. Hundreds of pressure tests to full working pressure have proven its ability to maintain a positive seal. Tests performed in an industry program sponsored by 22 companies including three major BOP manufacturers, proved the Shaffer Spherical element lasts two to four times longer than elements in other annular preventers. The element retains its ability to return to the opened position longer than other sealing packers do. The long sealing life of the element gives Shaffer Sphericals a high degree of reliability and keeps maintenance costs, as well as operating costs, to a minimum.

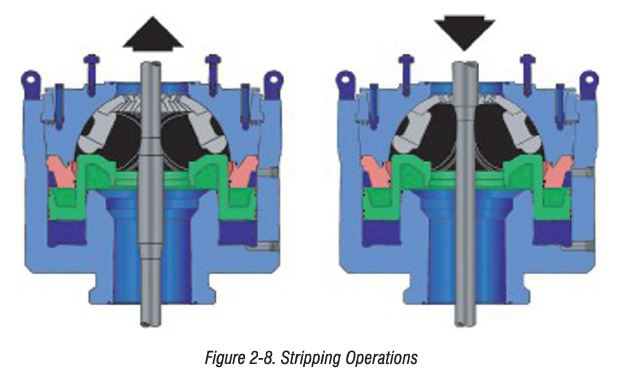

The success of NOV's Shaffer Sphericals is due primarily to the ruggedness and reliability of their sealing element. Hundreds of pressure tests to full working pressure have proven its ability to maintain a positive seal. Tests performed in an industry program sponsored by 22 companies including three major BOP manufacturers, proved the Shaffer Spherical element lasts two to four times longer than elements in other annular preventers. The element retains its ability to return to the opened position longer than other sealing packers do. The long sealing life of the element gives Shaffer Sphericals a high degree of reliability and keeps maintenance costs, as well as operating costs, to a minimum. Stripping operations are undoubtedly the most severe application for any preventer because of the wear the sealing element is exposed to as the drill string is moved through the preventer under pressure. To prolong sealing element life, it is important to use proper operating procedures when stripping. The recommended procedures are:

Stripping is smooth with a Shaffer Spherical because the element opens and closes so easily. The steel segments molded into the rubber make metal-to-metal sliding contact with the sphere of the housing. This provides a much lower coefficient of friction than rubber-to-metal contact. Well pressure assists will not cause it to oversea!, since the element's design and method of energization counteract the well bore pressure acting on the piston. During stripping out, well pressure and pipe movements are in the same direction. Rubber compresses firmly against the steel segments at the top of the element, but rubber at the bottom is only lightly compressed. This creates a "funnel effect" that makes it easy for a tool joint to enter the sealing element. Hydraulic pressure bleeds off, allowing the element to expand and accommodate the larger O.D. of the tool joint.

When stripping in, well pressure and pipe movement oppose each other. Well pressure compresses the rubber portion of the element against the steel segments as the tool joint moves down into the Spherical.

Sealing elements are available in natural and Nitrile rubber compounds. This allows the Spherical to be fitted for any type of service water base mud, oil base mud, and low temperature. Natural rubber offers excellent fatigue and wear life in water base muds, and operates well in lower temperatures. This allows the Spherical to be fitted for any type of service; water base mud, oil base mud, and low temperature.

With the single and dual snubbing BOPs operation, time is reduced by eliminating conventional ram-to-ram snubbing. Both single and dual snubber blowout preventers have a working pressure of 5,000 and 10,000 psi. And just like the Spherical BOPs, the snubbers utilize the Shaffer 10,000 psi spherical packing element with its field proven design. This explains why there is a long life under the harsh snubbing conditions of passing tool joints and couplings through the element.

In these single and dual snubbers, maintenance is also made faster and easier. The two-piece snubbing element enables easy replacement with pipe in the well. For more assistance in rapid removal of the element, there is a hydraulically operated quick-release bonnet and an easy lift upper housing. The easy-lift upper housing further assists in rapid snubbing element removal with hydraulic cylinders integral to the BOP housing. In all, only eight minutes are needed to replace a snubbing element.

View Packing Elements and Seal Kits from World Petroleum Supply.