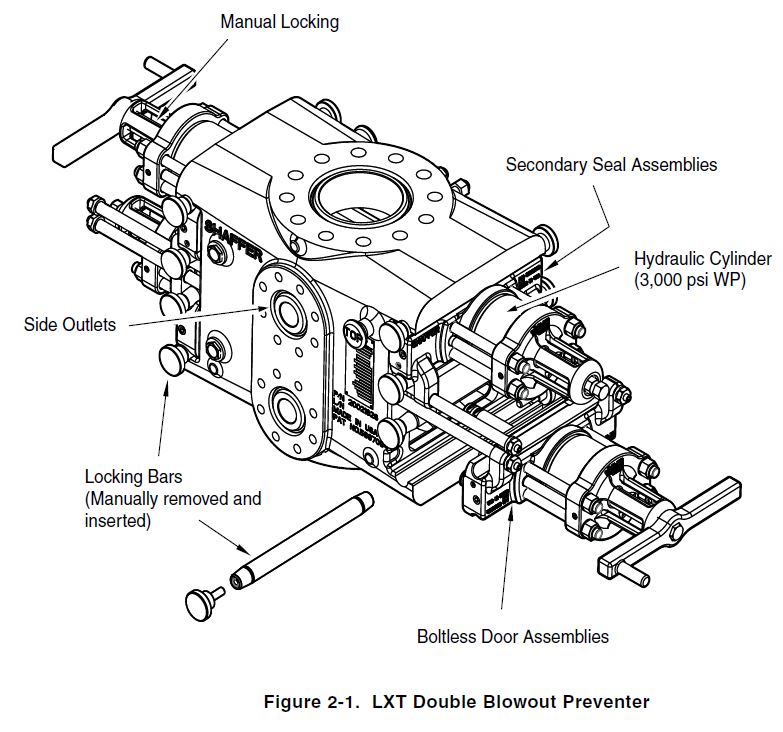

The Shaffer® hydraulic operated Model LXT™ ram blowout preventer (LXT BOP) with manual locking cylinders provides a rugged, reliable preventer that is easily serviced in the field (see Figure 2-1).

Special features include:

The manual lock LXT BOP is available in single and double models. Contact World Petroleum Supply Sales for special configurations. This manual provides the installation, operation, and maintenance procedures for standard manual lock LXT BOP models with manual lock operators. The manual lock operators are used to close the ram assemblies on the drill pipe and close off the well bore. The manual lock operators require a hydraulic closing pressure of 1,500 psi (103 bar) to accomplish sealing the well bore pressure to the rated working pressure of the preventer. Maximum working pressure for the cylinders is 3,000 psi (206 bar). When the rams are hydraulically closed, the manual lock acme thread locking bolts are rotated clockwise to manually lock the rams in the closed position. National Oilwell Varco (NOV) supplies manual lock LXT BOPs in the sizes shown in the table titled "LXT BOP Available Sizes and Working Pressures" below.

LXT BOP Available Sizes and Working Pressures

Working Pressure Size

- 5,000 psi (345 bar) 7-1/16” (180 mm)

- 3,000 psi (207 bar) 7-1/16" (180 mm)

The Shaffer® RAM LXT BOPs available at World Petroleum Supply, Inc are designed for drilling and workover service. They are hydraulically operated and can be manually locked by turning a handle or handwheel (optional). The standard trim unit is suitable for internal H2S environments. Units can be manufactured for Arctic to -75 ºF (-59 ºC) and full H2S environmental services. Standard units can be retrofitted for full environmental H2S service. NOV preventers are manufactured in accordance with the American Petroleum Institute (API) specification 16A and the National Association of Corrosion Engineers (NACE) document NACE Standard MR 0175 (current revision).

View Packing Elements and Seal Kits from World Petroleum Supply.