Workovers rank among the most complex, difficult, and expensive types of well work. They are only performed if the completion of a well is terminally unsuitable for the job at hand. The production tubing may have become damaged due to operational factors like corrosion to the point where well integrity is threatened. Downhole components such as tubing, retrievable downhole safety valves, or electrical submersible pumps may have malfunctioned, needing replacement.

In other circumstances, the reason for a workover may not be that the completion itself is in a bad condition, but that changing reservoir conditions make the former completion unsuitable. For example, a high productivity well may have been completed with 5½" tubing to allow high flow rates (a narrower tubing would have unnecessarily choked the flow). Some years on, declining productivity means the reservoir can no longer support stable flow through this wide bore. This may lead to a workover to replace the 5½" tubing with 4½" tubing. The narrower bore makes for a more stable flow.

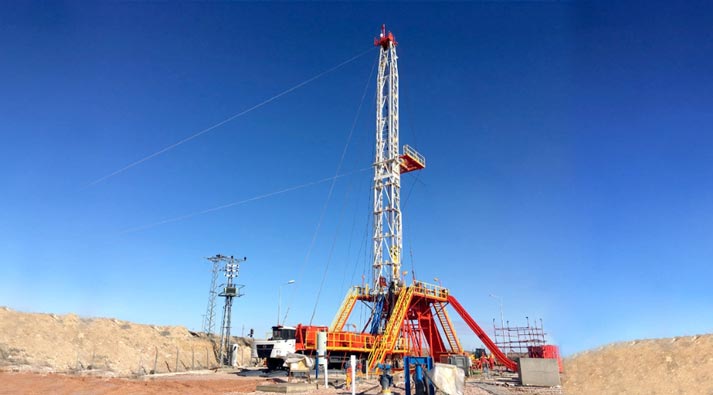

- source: WikipediaWorld Petroleum Supply, Inc. stocks the top Workover/Well Servicing Tools in the industry from leaders like Cavins Oil Well Tools, Westco International, NOV, BVM Corp., and Keystone Energy Tools. Their designs have been field-proven with features, and design to save money, time and enhance safety.